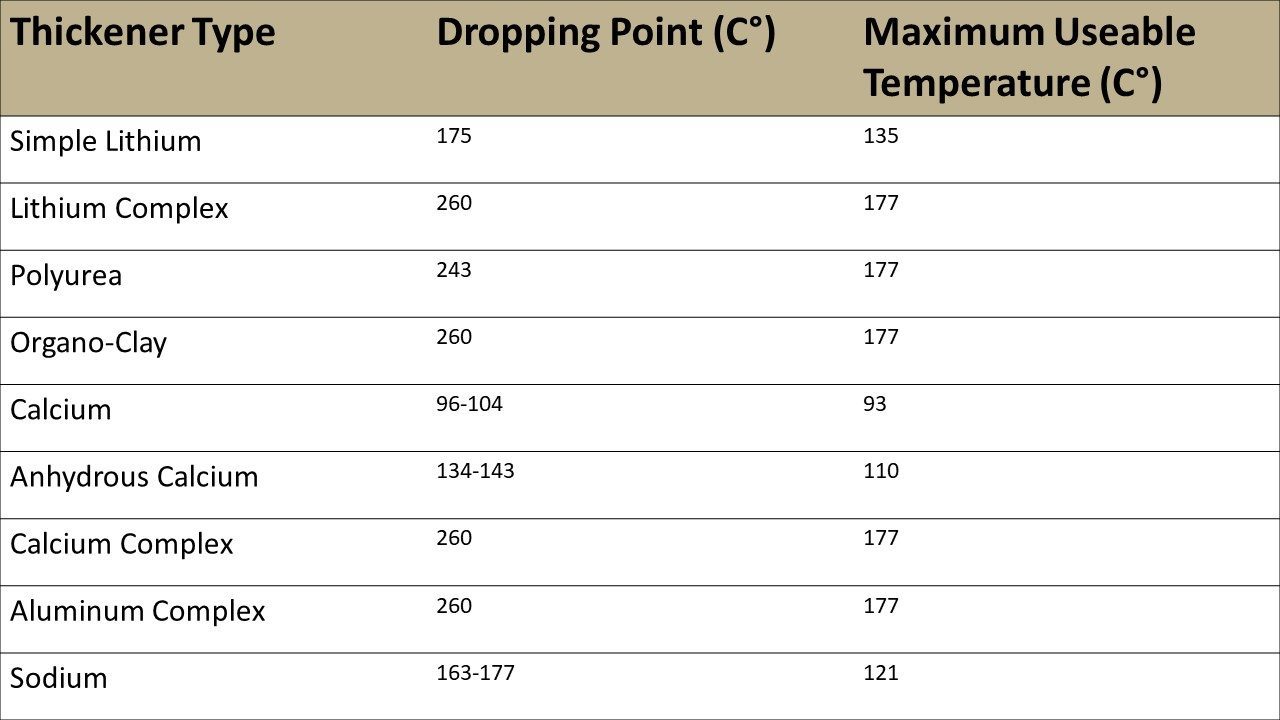

Industrial grease can be subjected to extreme temperatures, so it is important to choose a product with the ideal dropping point and maximum useable temperature. Dropping point refers to the temperature at which a grease passes from a semi-solid to a liquid. This is the highest temperature where grease will retain its structure, not the maximum temperature at which it should be used. That number can vary quite a significantly from dropping point. To avoid confusion as to which is which, check out our comparison chart before you buy.

Knowledge Center Links:

-Oil vs. Grease: What's the Difference?

-Conventionals, Synthetics and Blends

-Important Lubricant Organizations

Lubricants 201

Lubricants 301

-Handling and Storing Lubricants

-Lubricant Maintenance and Analysis

Articles

-Dropping Point/Useable Temperature Chart

-The Right Motor Oil for the RIght Temperature

-Specially Tailored Lubricants Can Power Performance

-This Winter, Choose the Right Lubricant

-Benefits of Universal Tractor Fluids in Construction Equipment

-Chain Lubrication - Penetration is the Key to Success

-When Choosing Grease, Practice Due Diligence

-Metalworking Fluids: A Product Overview

-What's That Smell? Microbiological Growth in Metalworking Fluids